| Foam Rising Analyzer |

Manufactured by

FOAMAT, GERMANY |

| |

|

| Foam Qualification System FOAMAT Measuring Physical Parameters During Foam Formation |

| Cat. # |

제 품 명 |

|

| 100 |

Foam Rising Analyzer |

견적요청 |

|

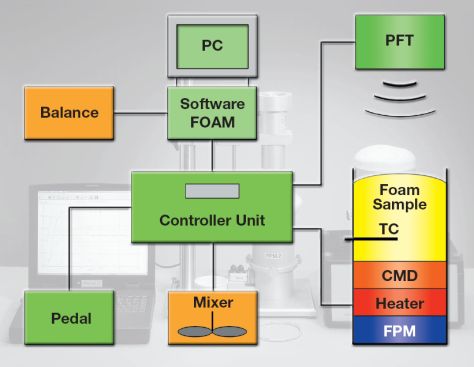

Fig. 1. The foam qualification system FOAMAT with the ultrasonic fan sensor PFT, a thermocouple, and the pressuremeasurement devices FPM 2 and FPM 150. The measurement sequence and the data processing are controlled by the software ,,FOAM” (left).

* covered by several patents |

- Measuring Physical Parameters During Foam Formation

- Simultaneous measurement of foam rise height, reaction temperature, rise pressure, curing, weight loss and viscosity

- Master curves for quality assurance testing in production control (ISO 9001)

- Easy to use Windows based FOAM software

- High performance sensors for all foam, types

- Measuring Physical Parameters During Foam Formation

- Simultaneous measurement of foam rise height, reaction temperature, rise pressure, curing, weight loss and viscosity

- Master curves for quality assurance testing in production control (ISO 9001)

- Easy to use Windows based FOAM software

- High performance sensors for all foam, types

|

| |

|

장비개요

→ 본 장비는 Polyurethane용 원재료(Poly & Isocyanate)의 화학적 반응과정에서의 물리적, 화학적 특성을

측정할 수 있다.

→ Cream Time, Gel Time, Rise Time를 통해 원재료의 Flowability, Moldability, Curability를 예상할

수 있으며, Foam의 Max. Height를 통해서는 Density, Flowability를 예측하며 상대적인 비교가 가능하다.

→ 측정항목 중 Shrinkage를 통해 생산 Line에서의 Crushability 및 Shrinkage 특성을 예측할 수 있다.

→ Foam 내부의 압력변화, 온도변화를 통해 Cell Open 특성, Mold PU 제품의 Mold 내압, 성형성 등을

예측하며, PU Foam의 발열 반응정도 및 경화 속도를 예측할 수 있다.

→ 점도 (Viscosity)의 Graph 확인을 통해 Rise Profile 관찰 및 Flowability를 예측할 수 있다.

→ Master Curves를 통해 제품의 품질관리가 가능하며, 모든 System은 Software를 통해 작동되며, Data의 편집,

운용등 광범위한 활용이 가능하다. |

| |

|

Rise Height and Rise Profile Measurement

The classic method for characterizing foams is to determine the rise height or rise profile by measuring the change in height due to the expansion of the foam sample in a cup, a cardboard box or a cylindrical container. The start time is generally accepted to be the start of the reaction between the mixed components A (polyol + additives) and B (isocyanate) after mixing. The rise time is the time which elapses until maximum expansion has occurred. The patented ultrasonic fan sensor PFT of the FOAMAT® system (Figs. 1, 2) can be used for all types of foams, including rigid foams with large heat release. The rise profile is the fingerprint of a foam. During quality assurance testing, it is compared with given master curves. A master curve (Fig. 3) is a tolerance band showing the margins of the rise profile for a “good” foam sample. Rise height measurement is still the standard test in foam qualification. With the FOAMAT® system new measurement techniques have become available, revealing more detailed information of the foam generation process.

Fig. 2. The patented ultrasonic fan sensor PFT ventilates the surface of the rising foam.

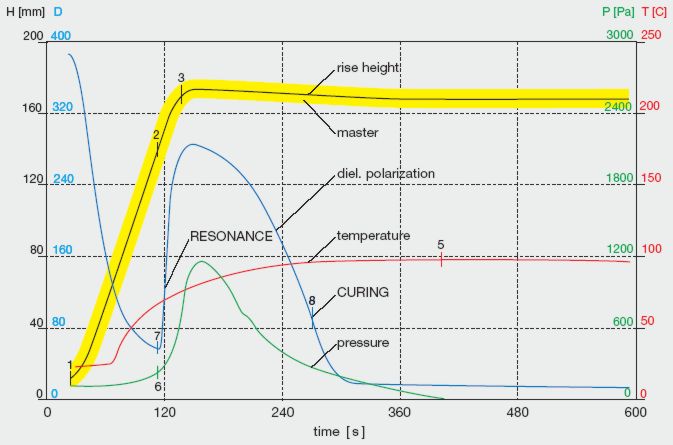

Fig. 3. The experimental data for rise height, temperature, rise pressure, dielectric polarization, and loss of mass are recorded simultaneously by the software FOAM and are displayed in a graph. The figure shows the curves for a semi rigid foam measured with FOAMAT and FPM/CMD2. |

| |

|

Reaction Temperature

The exothermal cross linking reaction causes the temperature increase in the foam sample. Thin thermocouples are ideal for measuring the temperature inside the foam because they have a low heat capacity and are easy to handle. They interfere little with the foam formation and can be used repeatedly |

Foam Pressure Measurement

-Gel Point 의 성향을 판단할 수 있습니다.

-Foam의 압력 변화를 확인할 수있습니다.

-CMD(Curing Monitor Device)와 같이 결합하여 사용된다.

-측정 Data는 Foam의 높이 변화, 내부 온도변화 등과 같이 확인할 수 있습니다.

-Sample양에 따라 두가지 Model (FPM2와 FRM150)이 있습니다

Fig. 4.FPM 2 on the stand of the Foam Qualification System FOAMAT®.

|

Viscosity Determination

A particular advantage of measuring the pressure by the FPM is that it allows the viscosity of the foam to be calculated directly from the experimental data provided by FOAMAT®. This is achieved by using the Hagen-Poisseuille viscosity model. The model starts on the assumption that the viscosity is determined by the force necessary to move a longitudinal element of foam at a specified speed through a tube, which is the FPM in this case. The reaction force is obtained directly from the rise pressure. The pressure data and the rise height curve measured in the FPM are sufficient for calculating the viscosity vs. time. For producers, the viscosity gives additional information for optimizing the process control in moulded foam production.

|

Dielectric Polarization Measurement / sensor CMD (Curing Monitor Device)

-Rising Foams의 절연체 편광 측정을 하는데 이용된다.

-Foam이 반응하는 동안에 Curing 상태와 Sample의 성향을 판단할 수 있다.

-FPM(Foam Pressure Measurement)와 같이 결합되어 FPM Foam의 압력 변화를 확보할 수 있다.

-Flexible, Semirigid와 Rigid Foam등 각각 다른 성향의 측정 결과가 나타난다.

-두가지 Model (CMD2, CMD150)이 있다.

Fig. 5. The polarization sensor CMD which is integrated into the FPM device measures the dielectric polarization of a foam sample simultaneously with the rise pressure. Right: the foam specimen in the removed cardboard cylinder.

|

| Advanced Test Container ATC

Undefined test container temperatures spoil the correlation between the test result and the production situation. PIR foams require external heat to react and cure properly. Otherwise these formulations remain sticky and voids appear. To overcome this, Format Messtechnik GmbH has introduced the temperature controlled Advanced Test Container ATC (Fig. 6). Another advantage of the new precise temperature controlled test container is the better reproducibility of the measurement data compared to non temperature controlled systems.

Fig. 6. The Advanced Test Container ATC is a temperature controlled test container giving most reproducible and production near test results.

|

Box Foam Setup

The Box Foam Setup comprises the Box Foam Container BFC 200, the extended mechanical set and a metal sheated thermocouple. The Box Foam Setup is specially designed to measure the rise height and the core temperature of slabstock foam samples. The BFC 200 is made of Pertinax walls forming a cube with an edge length of 200mm. For easy access to the finished foam sample two of the walls are hinged and can be flapped aside. A thermocouple holder is mounted at the upper edge of the BFC 200. It has a boring at an angle of approximately 45 degrees for inserting a thermocouple into the center of the foam. The extended mechanical set is larger than the standard mechanical set and is equipped with a second cup receptacle, turned to the right hand side of the stand.

Fig. 7. The BFC 200 is placed onto the base plate of the extended mechanical set. The thermocouple is inserted into the center of the foam.

|

Balance Integration / Weight loss masurement

-Sample의 주입량을 확인할 수 있다.

-Foaming이 되는 동안에 Weight loss를 측정할 수 있다.

-CMD(Curing Monitor Device)와 같이 결합하여 사용된다.

-측정 후 밀도 (Density) 값을 산출하는데 적용된다.

Fig. 8. For measuring the loss of mass, the test cup is placed on a laboratory balance with serial data interface.

|

System Configuration

The complete Foam Qualification System FOAMAT® and its periphery is shown in Fig. 8. The mixer operation is controlled by the software FOAM according to the user’s input. The controller unit and the balance are connected to the PC. The foot switch (pedal) is used to start a measurement cycle and to operate the mixer off-line.

Fig. 9. System survey of the Foam Qualification System FOAMAT and its periphery.

top |

| |